Discover our Industrial Grade Laser Cleaning machines

Facing manufacturing challenges? We are expert in laser welding, cleaning, texturing and marking. We provide turnkey machines and OEM systems tailored to your production requirements. Our range of offerings also includes free part testing, process studies and rental machines.

GET YOUR PARTS TESTED FREE – WE CAN PICK UP

We test various laser configurations on samples & coupons, validate results to your specs, and provide a detailed report with video, measurements, speeds, and system recommendations. We also return the samples for in-house validation.

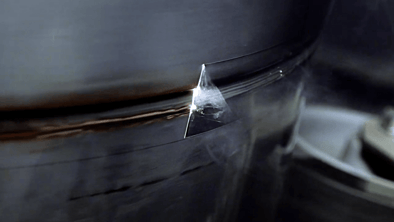

LASER OXIDE REMOVAL

This process is used to clean metal surfaces before surface treatments, especially before aluminum welding. It is also used after welding to remove stainless steel oxides.

LASER PAINT REMOVAL

This method vaporizes paint while leaving the underlying surface intact. Selective paint removal can be used to replace part masking, clean painting tools, prepare welding areas, salvage parts with paint defects, and more.

LASER PAINT REMOVAL

This method vaporizes paint while leaving the underlying surface intact. Selective paint removal can be used to replace part masking, clean painting tools, prepare welding areas, salvage parts with paint defects, and more.

LASER SURFACE CLEANING FOR ADHESIVE BONDING

Laser surface cleaning can prepare parts for adhesive bonding, making sure no oxides and any other contaminants like oil and dust interfere with the bonding process. When needed, the laser can also roughen the surface to promote mechanical interlocking.