FACING MANUFACTURING CHALLENGES?

We are expert in laser welding, cleaning, texturing and marking. We provide turnkey machines and OEM systems tailored to your production requirements. Our range of offerings also includes free part testing, process studies and rental solutions to address your production needs.

GET YOUR PARTS TESTED FREE – WE CAN PICK UP

We test various laser configurations on samples & coupons, validate results to your specs, and provide a detailed report with video, measurements, speeds, and system recommendations. We also return the samples for in-house validation.

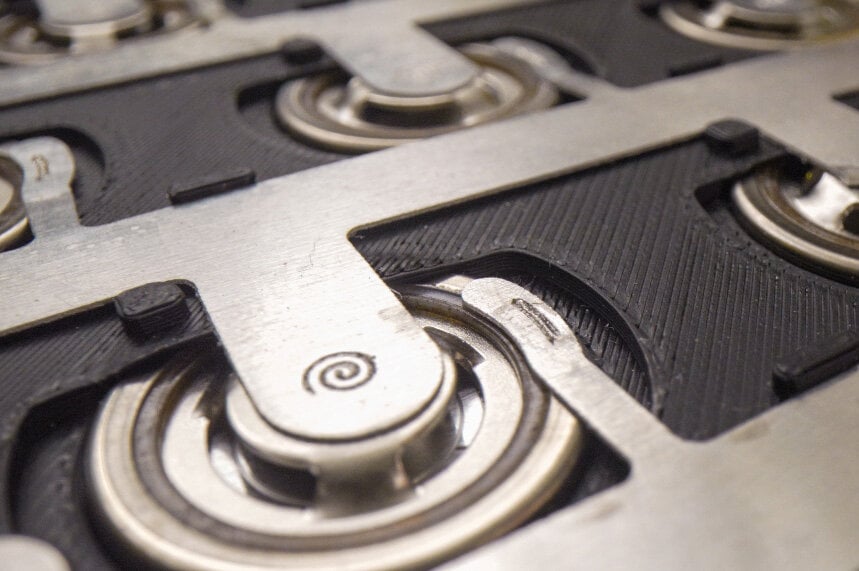

LASER WELDING BUSBAR TO CELL CONNECTION

Laser welding's high flexibility, precision, and speed make it an increasingly popular method in the battery industry. It allows customizable welds to fit small spaces, enabling diverse module designs. As a non-contact process, it can access areas often unreachable by ultrasonic or resistance welding.

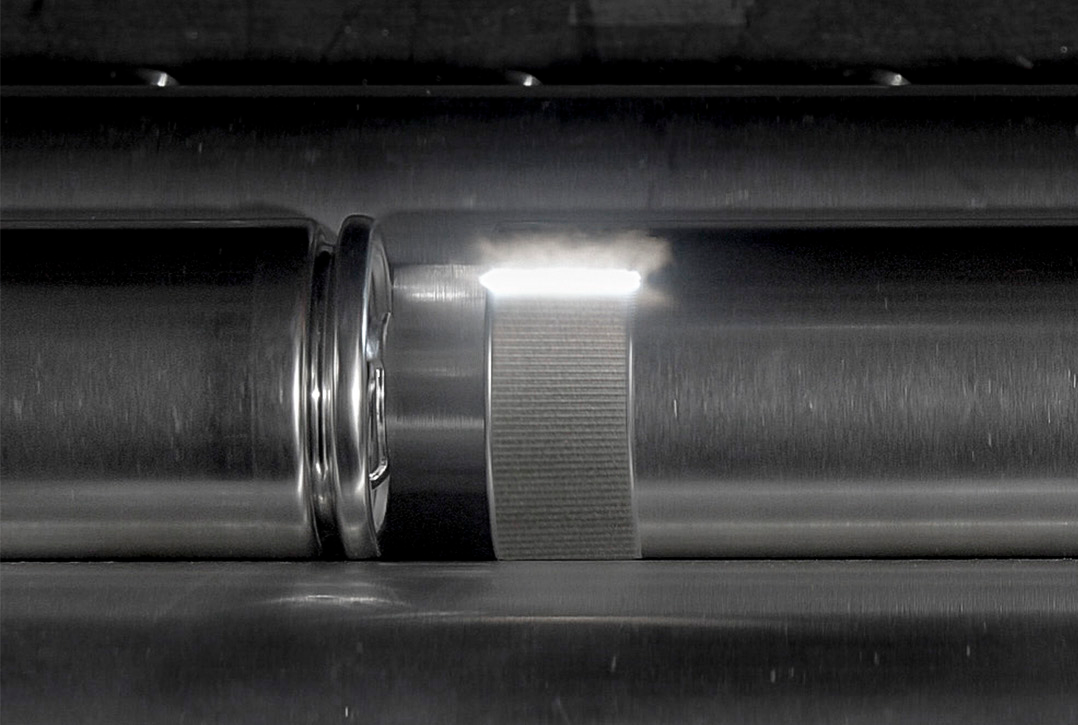

LASER CLEANING BEFORE WELDING AND GASKETING

Such preparation before gasketing improves the bonding strength and sealing properties. As for laser cleaning of cell tabs before

laser welding, it has been shown that this process helps produce good welds every time by reducing the amount of false negatives

reported by LWM devices.

LASER CLEANING BEFORE WELDING AND GASKETING

Such preparation before gasketing improves the bonding strength and sealing properties. As for laser cleaning of cell tabs before

laser welding, it has been shown that this process helps produce good welds every time by reducing the amount of false negatives

reported by LWM devices.

LASER TEXTURING FOR THERMAL AND STRUCTURAL ADHESIVES

Laser texturing enhances battery structural resistance and cooling by creating optimal surface roughness, improving heat transfer and bonding for adhesives. This process can be tailored to adhesive needs and combined with laser cleaning for comprehensive surface preparation in a single step.

LASER MARKING FOR PERMANENT TRACEABILITY

Laser marking is a fast, precise, and consistent process that

creates permanent markings for optimal traceability.

Serial numbers, data matrix codes, and other types of identifiers

can be etched within less than 100 milliseconds.

LASER MARKING FOR PERMANENT TRACEABILITY

Laser marking is a fast, precise, and consistent process that

creates permanent markings for optimal traceability.

Serial numbers, data matrix codes, and other types of identifiers

can be etched within less than 100 milliseconds.